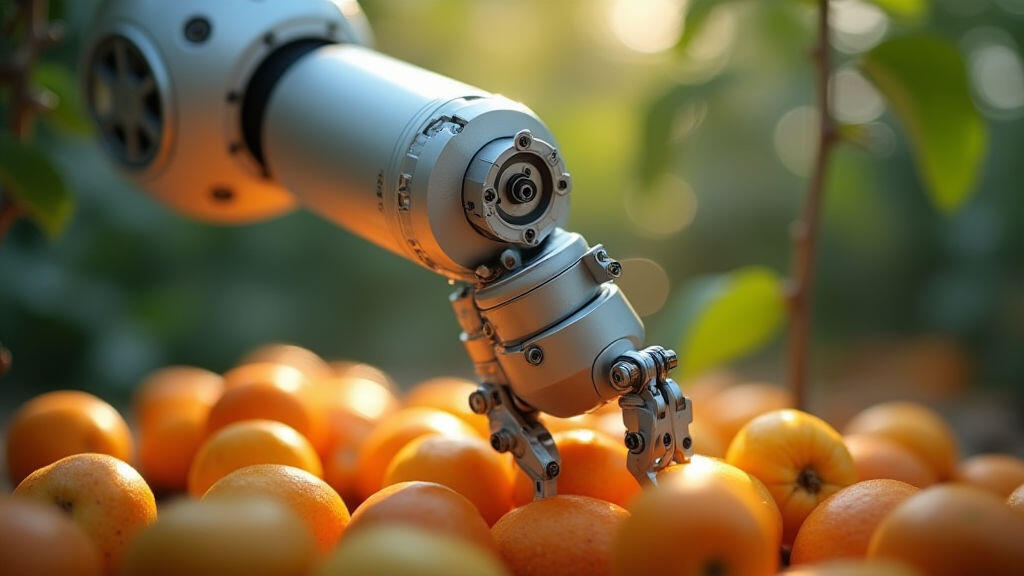

The agricultural sector is undergoing a rapid transformation, fueled by the need for increased efficiency, precision, and sustainability. This evolution is heavily reliant on technological advancements, and micro DC gear motors are emerging as critical components driving this change. From automated harvesting systems to smart irrigation solutions and precision planting equipment, these compact, powerful motors are enabling significant upgrades to agricultural machinery. This article will explore various configuration strategies for micro DC gear motors in agricultural equipment, highlighting benefits, challenges, and future trends, especially in the context of the ongoing push for sustainable farming practices and the integration of IoT (Internet of Things).

Traditional agricultural machinery relied on larger, less efficient motors. However, the demands of modern agriculture – requiring greater maneuverability, reduced energy consumption, and the ability to perform complex tasks – necessitate smaller, more versatile solutions. Micro DC gear motors fit this bill perfectly. Their compact size allows them to be integrated into space-constrained applications, while their high torque-to-size ratio provides the power needed for demanding tasks. Moreover, they’re increasingly energy-efficient, aligning with the growing emphasis on minimizing the environmental footprint of farming.

The integration of IoT is also accelerating the adoption of these motors. Sensors coupled with micro DC gear motors allow for automated control and data collection, enabling farmers to optimize processes and make data-driven decisions. For instance, a micro DC gear motor could control a valve in an automated irrigation system, adjusting water flow based on soil moisture sensor readings transmitted via an IoT platform.

The optimal configuration of a micro DC gear motor depends heavily on the intended application. Here are some common strategies:

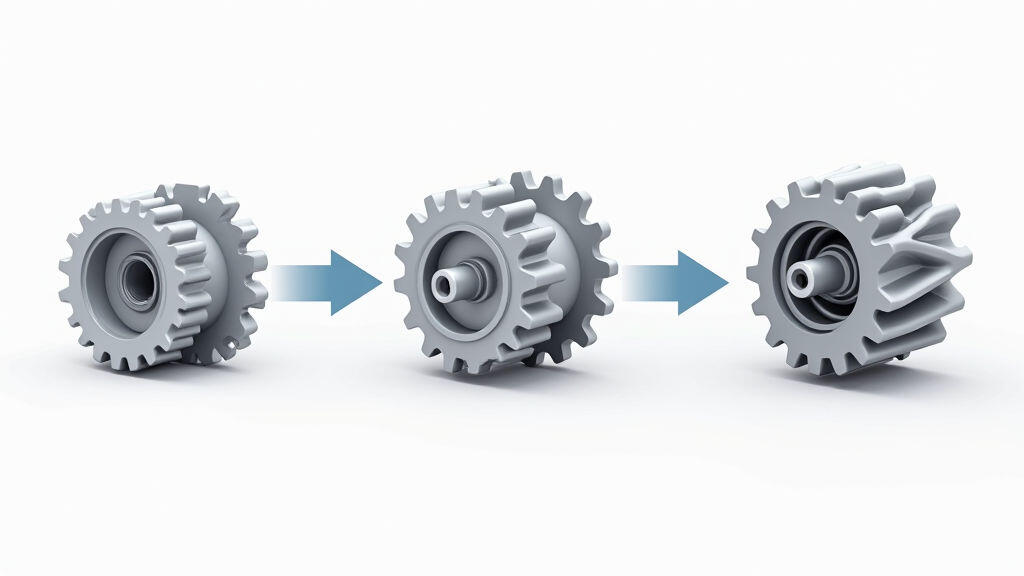

1. Direct Drive vs. Geared Drive:

While some applications benefit from the simplicity of a direct drive (where the motor shaft is directly connected to the load), most agricultural equipment requires higher torque. This is where gearboxes come in. Gearboxes multiply the motor's torque, allowing it to handle heavier loads.

2. Reduction Ratio Selection:

The reduction ratio of the gearbox significantly impacts the output torque and speed. Selecting the right ratio is crucial for optimal performance. For soil cultivation equipment, a higher reduction ratio is needed for powering tillers or cultivators. Precision planting systems often require lower reduction ratios for accurate and precise movements. A detailed calculation of required torque and speed is vital before choosing a gearbox, leveraging resources like motor torque curves and load requirements specified by the agricultural equipment manufacturer.

3. Mounting and Integration Considerations:

The physical mounting of the motor is essential for reliable operation. Agricultural environments are harsh, with exposure to dust, moisture, and vibration. Therefore, robust mounting solutions using vibration-dampening materials are crucial. Sealed enclosures are also necessary to protect the motor from environmental contaminants. Furthermore, minimizing the motor's footprint during integration is a key consideration, especially in compact machinery designs.

4. Control Strategies and Feedback Mechanisms:

Modern agricultural equipment often relies on sophisticated control systems. Micro DC gear motors can be integrated into these systems using various control strategies:

The adoption of micro DC gear motors offers numerous advantages for agricultural equipment:

Despite the numerous advantages, several challenges need to be addressed:

MES-Drive specializes in high-performance micro DC gear motors tailored for demanding applications. Our motors are designed for durability, energy efficiency, and precise control. MES-Drive offers a wide range of gearboxes and configuration options to meet the specific needs of agricultural equipment manufacturers. We’re committed to developing innovative solutions that contribute to sustainable farming practices and empower farmers with the technology they need to succeed. Through our collaborations and technical support, we assist in optimizing motor configurations and integration processes.

The future of micro DC gear motors in agriculture is inextricably linked to the Internet of Things (IoT) and the growing emphasis on precision agriculture. We expect to see:

In conclusion, micro DC gear motors are playing a pivotal role in the modernization of agricultural machinery. By carefully considering configuration strategies, manufacturers can leverage these motors to achieve significant improvements in efficiency, precision, durability, and sustainability. As the agricultural sector continues to embrace IoT and data-driven practices, the demand for advanced motor solutions will only increase, positioning MES-Drive and our partners at the forefront of agricultural innovation. These advancements are especially relevant in the context of current discussions about food security and the need for more sustainable and efficient farming methods.

Leave A Reply

Your email address will not be published. Required fiels are marked